|

Process of manufacture

Stuffing containers with activated carbons. Because the performance varies, a large container is needed to upgrade the performance.

Low density

Pressing with extremely high density and cast at high temperature.

The materials used are limited because of pressing at high temperature.

High density

A lot of initial cost is required because many molds are necessary.

|

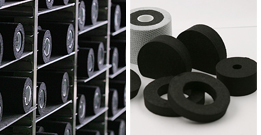

Process of manufacture

All the materials are mixed with solution, cast and dried.

Adjustment of the density is possible.

Any materials can be mixed.

The items of removal materials are increased with mixing of special materials.

Mixing with special materials such as activated carbons further makes it permeable and less collapsing.

Making the mold is so easy that desirable sizes and samples for designed performances can be promptly implemented

The productivity is better than the conventional one and the mass production can be soon ready and save the cost.

|

Density

Adsorption performance is lowered if the density is low.

If the density is too high, water passing resistance is deteriorated. |

Density

The adjustment of the density enables it to adjust the water passing volume and the performance. |

Adhesive agents

A lot use of adhesive agents makes the hardness level high and difficult to be collapsed.

A lot of compounding of adhesive agents makes the holes of activated carbons stuffed up and the absorption performance is deteriorated.

Because organic binder is used, a lot of bacteria grow and results in using a lot of silver activated carbons.

Reaction of chemical material in the water causes troubles such as odor and others. |

Adhesive agents

By making the binder as extremely less as possible, we can get the maximum performance of the materials.

The performance is 1.5 times.

With the use of inorganic binder, bacterial growth is prevented and very hygienic.

There is no reaction with chemicals contained in water and less troubles such as odor. As the hardness level of the filter gets high, the collapse gets further less. |